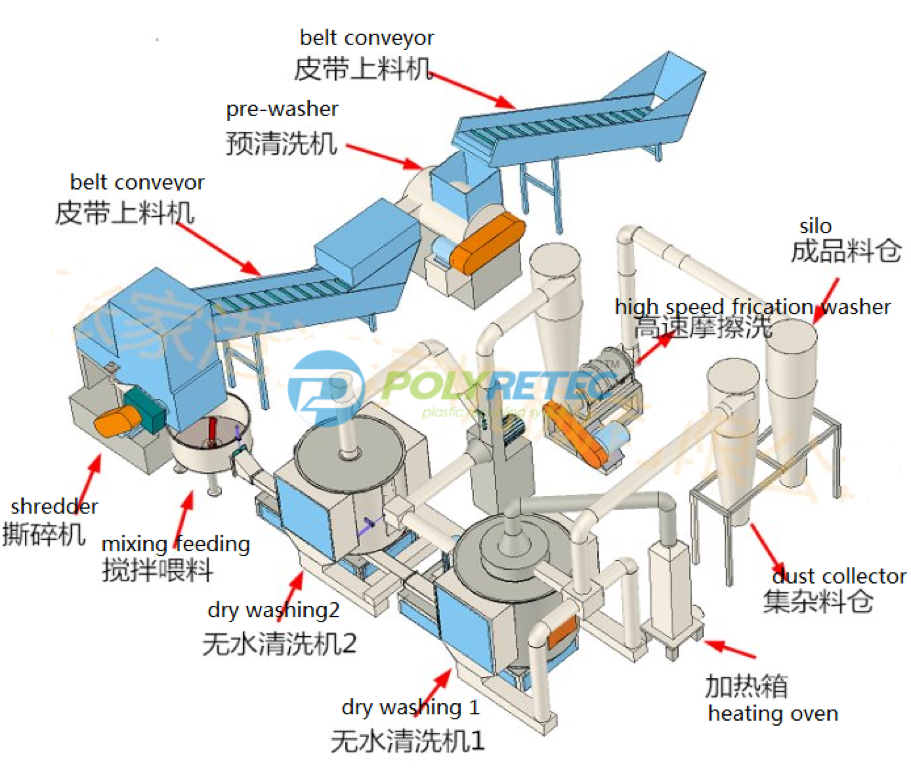

Equipment introduction

Waterfree cleaning recycling production line, the use of friction, grinding, collision and other physical force, so that waste plastic pieces and hard objects, fragments and fragments between the collision, friction and grinding. Attached to the plastic sheet dirt and metal impurities, sent to the cyclone and cyclone dust removal and separation, and ultimately get a clean waste plastic pieces.

Process:

According to the principle of waste plastic water recycling, the process consists of three parts: pretreatment - cleaning - separation

Scope of application:

Film categories: PE waste film, PP waste film, PVC waste film, agricultural film, industrial film waste film

Woven bags: feed woven bags, woven bags of cement, flour woven bags, space bags, tons of bags, etc.

Model | PTC-500 | PTC-1000 |

Output(kg/h) | 500kgh | 1000kgh |

Total power | 200kw | 310kw |

Advantages:

Anhydrous cleaning and recycling equipment increases product quality and material yield. As the recovered net material is already dried, the energy required for extrusion is reduced. The cost of cleaning per ton of water is less than the cost of traditional cleaning

This is 30% lower.

Equipment maintenance also saves costs. Due to the relatively clean separation of impurities, follow-up granulator screw, barrel, filters and other vulnerable parts are effectively protected. Air bubbles are no longer produced during the process, and the filter replacement interval is significantly longer. For the screw and barrel, their service life also extended to the original

Economic Comparsion :(according to recycle one ton raw material )

| Traditional washing and dewater | Traditional washing and squeezer | Dry washing line |

Power consumption | 180kwh | 350kwh | 290 |

Water consumption | 40ton | 40ton | No water |

Electric for granulator | 500kwh | 400kwh | 350kwh |

Water+electric | Profitided in china | Big scale company in china | The future development direction ( no water, and dust collect ) |

About our service:

Waste plastic dry washing line Before-sale

1、Introduce products and applications detain

2、Recommend suitable solution

3、Provide with reference information

4、Offer lab for test

During Manufacturing

1、Provide with layout and engineering conditions

2、Inform the project processing status

3、Offer other documents

After-sale

1. Provide with installation, commissioning and training

2. Register and record customer information

3. Offer spare parts

4. Provide with necessary technical support for new application

5. Visit customer regularly and correct information

Why choose us

1.Lower investment cost for a high quality and durable machine;

2. Low energy consumption with high production output;

3. Overseas installation and training are available;

4. Machine warranty with spares in stocking and in-time delivery;

5. Fast machine delivery and installation: POLYTEC produces on an average of 10 sets of plastic machines per month and can deliver the machine faster than most manufacturers. The regular delivery time of an POLYTEC recycling machine is 60 days.